In the dynamic world of construction, innovations are constantly emerging to address long-standing challenges. One such breakthrough is the development of anti condensation felt, a material designed to tackle the issue of condensation in metal roofing systems.

What is Anti condensation Felt?

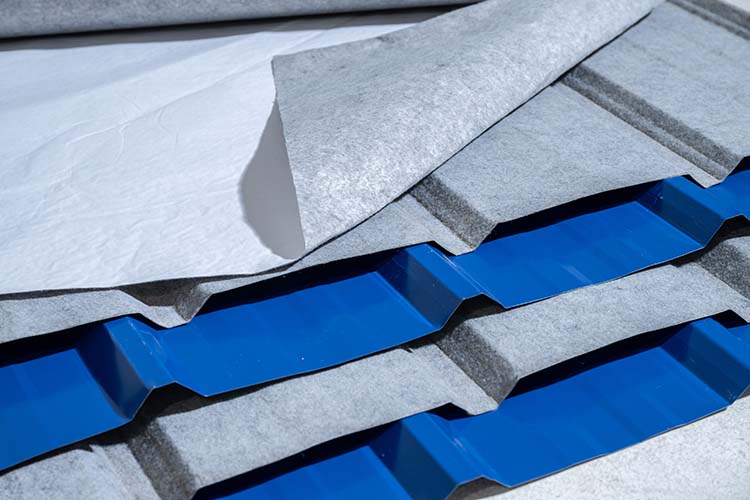

Anti-drop felt is a cutting-edge material specifically engineered to prevent condensation from forming on the underside of metal roofs. Condensation can lead to water droplets that cause damage to the structure and its contents. This felt works by absorbing and retaining moisture, preventing it from dripping onto surfaces below.

How Does It Work?

The technology behind anti condensation felt is both simple and effective. The felt is made from a highly absorbent material that captures moisture when the temperature and humidity conditions reach the dew point. This moisture is then held within the felt until conditions change, allowing the moisture to evaporate back into the air. This process ensures that the underside of the metal roof remains dry, significantly reducing the risk of water damage.

Benefits of Anti condensation Felt

Cost-Effective: Anti-drop felt is a more economical solution compared to traditional insulation and vapor barriers. It reduces the need for additional materials and labor, making it a cost-effective choice for builders and homeowners.

Durability: Unlike standard insulation and vapor barriers, anti-drop felt is resistant to ripping, tearing, and deterioration. This durability ensures a longer lifespan and less frequent replacements.

Ease of Installation: The installation process for anti-drop felt is straightforward and can be completed quickly. This ease of installation saves time and reduces labor costs.

Environmental Impact: By preventing condensation and reducing the need for additional insulation materials, anti-drop felt contributes to a more sustainable construction process. It minimizes waste and promotes energy efficiency.

Applications and Future Prospects

Anti-drop felt is primarily used in metal roofing systems, but its applications are expanding. It is becoming a popular choice for agricultural buildings, warehouses, and residential properties. As the construction industry continues to prioritize sustainability and cost-efficiency, the demand for anti condensation felt is expected to grow.

The future of anti condensation felt looks promising. Ongoing research and development are focused on enhancing its absorbent properties and expanding its applications. Innovations in this field could lead to even more effective solutions for managing condensation in various environments.

In conclusion, anti condensation felt is revolutionizing the roofing industry by providing a simple, cost-effective, and durable solution to the problem of condensation. Its benefits extend beyond just preventing water damage, contributing to a more sustainable and efficient construction process. As this technology continues to evolve, it is set to play a crucial role in the future of building materials.